The local thickness is a crucial measure in various fields, such as material science, manufacturing, and medical imaging. It provides valuable insights into the structural integrity, quality, and performance of objects or materials.

However, to gain meaningful and comprehensive insights, it is essential to effectively combine local thickness data with other relevant information. In this article, we will explore how to combine local thickness for better insights, enabling us to make more informed decisions and advancements in our respective fields.

What is Local Thickness?

Local thickness refers to the measurement of the average thickness in a specific region or part of an object or material.

It helps in understanding the variations in thickness within an object, identifying potential areas of vulnerability, and assessing the overall quality of the structure.

Importance of Local Thickness

Local thickness is crucial in multiple industries and applications. Some of the key reasons why it is important include:.

Determining Structural Integrity

The local thickness measurement allows us to identify areas of concern within a structure. By assessing the thickness variations, we can better understand the potential risks and vulnerabilities associated with the object or material.

This insight helps in ensuring the structural integrity and avoiding failures or accidents.

Optimizing Manufacturing Processes

For manufacturers, local thickness data is instrumental in optimizing their production processes. By identifying variations in thickness, they can refine their manufacturing techniques, adjust parameters, and improve overall product quality.

This not only enhances customer satisfaction but also reduces wastage and costs.

Enhancing Quality Control

In industries where precision and quality control are paramount, local thickness analysis plays a vital role.

By combining local thickness measurements with other quality control techniques, manufacturers can identify defects, inconsistencies, or deviations from desired specifications. This information helps in rectifying issues promptly, maintaining consistent quality, and meeting industry standards.

Identifying Performance Variations

In fields such as automotive or aerospace engineering, local thickness analysis aids in evaluating the performance of components or structures.

By measuring the thickness variations, engineers can identify areas where the performance might be compromised. This information enables them to make necessary design modifications, resulting in improved performance and safety.

Combining Local Thickness with Other Data

To gain comprehensive insights and make informed decisions, it is important to combine local thickness data with other relevant information. Here are some effective ways to achieve this:.

1. Correlation with Material Properties

Local thickness measurements can be correlated with material properties such as tensile strength, elasticity, or density.

By analyzing the relationship between thickness and material characteristics, researchers or engineers can gain insights into how structural performance may vary based on thickness variations.

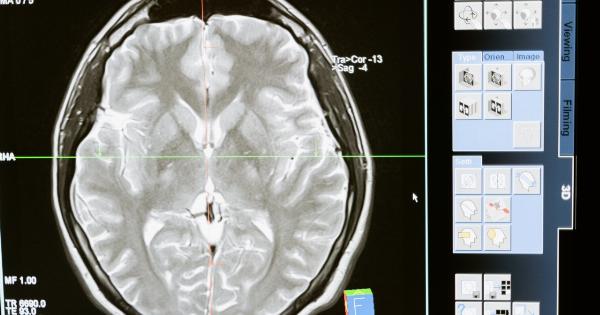

2. Integration with Non-Destructive Testing

Non-destructive testing techniques, such as ultrasound or X-ray imaging, provide additional data about the internal structure of objects or materials.

By integrating local thickness measurements with these techniques, a more holistic understanding of the object’s condition can be obtained. This integration allows for a comprehensive evaluation of both surface and subsurface features.

3. Statistical Analysis

Statistical analysis methods, such as regression analysis or hypothesis testing, can be employed to analyze the relationship between local thickness and other factors.

This approach helps in identifying significant variables that affect thickness variations and provides insights into the underlying dynamics of the object or material.

4. Machine Learning Algorithms

Machine learning algorithms can be trained using local thickness data along with other relevant features. These algorithms can then predict the behavior or performance of objects or materials based on their thickness profiles.

This combination of local thickness and machine learning enables predictive analytics and facilitates proactive decision-making.

Benefits of Effective Combination

By effectively combining local thickness data with other relevant information, several benefits can be achieved:.

1. Improved Accuracy

Combining data from multiple sources enhances the accuracy and reliability of the insights obtained.

Local thickness measurements, when considered in conjunction with other factors, provide a more complete picture and lead to more accurate assessments or predictions.

2. Comprehensive Understanding

An effective combination of local thickness data with other information allows for a comprehensive understanding of the object or material under analysis.

It enables researchers or engineers to evaluate the structural, functional, and performance aspects from various angles, uncovering hidden patterns or correlations.

3. Informed Decision-Making

By integrating different types of data, decision-makers can make informed choices and take appropriate actions.

The comprehensive insights obtained through effective combination empower them to mitigate risks, optimize processes, and drive improvements in their respective domains.

Conclusion

Local thickness measurement is a valuable tool for understanding the structural integrity, quality, and performance of objects or materials.

However, to gain meaningful insights, it is essential to effectively combine local thickness data with other relevant information. By correlating thickness with material properties, integrating with non-destructive testing, performing statistical analysis, and leveraging machine learning algorithms, we can maximize the benefits of local thickness analysis.

Through effective combination, we can make more informed decisions, enhance quality control processes, optimize manufacturing techniques, and drive advancements in various fields.