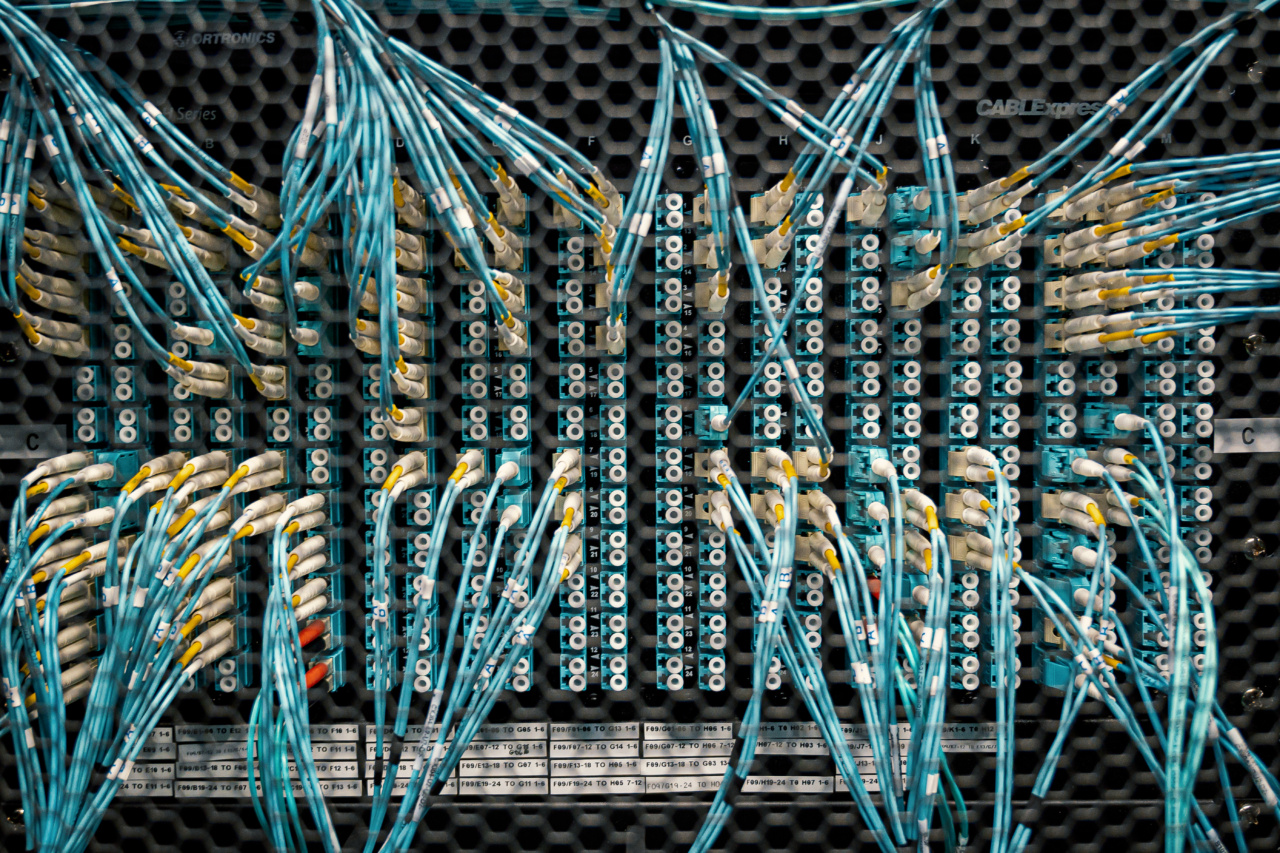

Optical fiber technology has revolutionized the way we transmit data. The use of optical fibers has enabled us to transmit data over longer distances and at faster speeds than ever before.

Optical fibers are slender, flexible, and transparent fibers made of glass or plastic that transmit light signals. While optical fibers are robust and long-lasting, performing maintenance activities on them can be a challenging task.

Optical fibers can malfunction due to several reasons, including breakage, bending, or contamination.

These malfunctions can lead to data loss, which can have severe consequences in various applications such as telecommunications, data centers, hospitals, and industrial control systems. In this article, we will discuss non-invasive optical fiber removal by suction.

Background

The primary method for repairing optical fibers that have malfunctioned is by cutting and splicing the fibers.

This method involves the use of cutting tools and stripping tools to remove the damaged portions of the fiber and then attaching the remaining sections. While this method effectively restores the fiber’s functionality, it is invasive and often leads to a longer network downtime.

Optical fibers are sensitive to contamination, and cleaning them can help prevent malfunctions. Invasive cleaning methods, such as scrubbing the surface of the fibers with cleaning agents, can also damage the fibers.

Non-invasive cleaning methods, such as using compressed air, have been in use for a long time.

Non-Invasive Removal of Optical Fibers by Suction

Suction technology has been in use for several industries, such as healthcare, where it is used to remove fluids from the body. In recent years, suction technology has been applied to the cleaning of optical fibers.

The non-invasive removal of optical fibers by suction involves the use of a vacuum suction pump to remove impurities from the fiber’s surface. The suction removes all the impurities, leaving the fiber clean and free of contaminants.

The suction is applied to the fiber surface through a specialized device attached to the suction pump. This device is designed to fit over the fiber and provide a seal around it, preventing air from entering the space between the fiber and the device.

The suction pump is turned on, creating a vacuum that sucks air and impurities from the fiber’s surface. The suction lasts for a few seconds, and the device is then removed, leaving the fiber contaminant-free.

Advantages of Non-Invasive Removal of Optical Fibers by Suction

The non-invasive method of optical fiber removal by suction has several advantages:.

Non-Invasive

The method is entirely non-invasive and does not involve cutting or removing any section of the fiber. This eliminates the risk of damaging or further breaking the fiber during the cleaning process.

Efficient

The suction method is fast and efficient, with a cleaning time of a few seconds. This means that downtime is significantly reduced compared to other invasive cleaning methods.

Cost-Effective

The suction method is cost-effective since it does not require expensive equipment or specialized tools.

This makes it accessible to fiber optics technicians and field engineers who can perform the task without the need for a specialist or extensive training.

Safe

The suction method is safe since it does not involve the use of cleaning agents or invasive procedures to clean the fiber.

This means that the fiber and the environment are not exposed to harmful chemicals, minimizing the risk of harm to people and the planet.

Applications of Non-Invasive Optical Fiber Removal by Suction

The non-invasive method of optical fiber removal by suction has several applications, including:.

Telecommunications

Optical fibers are extensively used in the telecommunications industry to transmit data over long distances.

The non-invasive method of optical fiber removal by suction helps technicians maintain and clean the fibers, ensuring that the network is running efficiently.

Data Centers

Data centers are essential in processing and storing a vast amount of data.

The non-invasive method of optical fiber removal by suction can help data center technicians perform maintenance activities on their fiber optics cables, which are critical in the transfer of data.

Hospitals

Hospitals use optical fibers in various medical equipment, including endoscopes and surgical instruments, where cleanliness is essential.

The non-invasive method of optical fiber removal by suction can help medical technicians maintain the cleanliness of the fibers, minimizing the spread of infections.

Conclusion

In conclusion, the non-invasive method of optical fiber removal by suction is a fast, efficient, cost-effective, and safe method of maintaining and cleaning optical fibers.

The method has several applications in various industries, including telecommunications, data centers, and hospitals, where fiber optics are extensively used. The suction method has eliminated the need for invasive cleaning methods that often result in prolonged network downtime, damage to the fiber, and exposure of harmful chemicals to the environment.