Food production has always been a challenge for humankind, with increasing worries about sustainable agriculture, animal welfare, environmental impact, and food security.

However, recent advancements in technology have provided innovative solutions to these concerns. One such breakthrough is the creation of FDA-approved “laboratory chicken” using cellular agriculture techniques.

What is Laboratory Chicken?

Laboratory chicken, also known as cultured chicken or cell-based chicken, is a meat product produced without the need for traditional animal farming.

Instead of relying on traditional livestock rearing methods, laboratory chicken is grown from animal cells in a controlled laboratory setting. These cells are obtained from a small sample biopsy of a live animal, without causing harm to the donor.

Through a combination of cell culture techniques and bioreactor technology, these cells are multiplied and differentiated to create meat that is biologically identical to conventionally produced chicken.

How is Laboratory Chicken Produced?

The production process of laboratory chicken involves several steps:.

1. Cell Isolation and Culture

To grow laboratory chicken, a small sample of live animal cells is obtained via a biopsy procedure that is harmless to the donor.

These cells, typically muscle cells or stem cells, are then isolated and transferred to a culture medium containing nutrients, growth factors, and antibiotics to encourage cell growth and proliferation.

2. Cell Multiplication

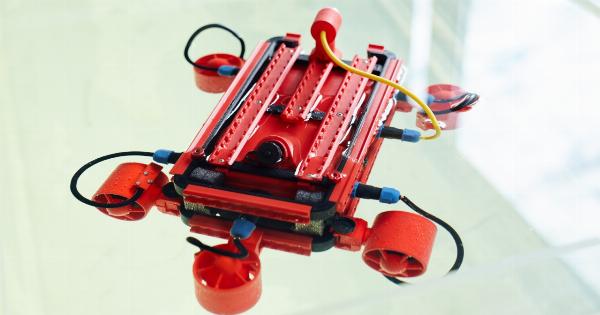

Once the initial cells are isolated and cultured, they are placed in a bioreactor – a controlled environment that provides optimal conditions for cell growth. The cells are supplied with nutrients, oxygen, and other factors required for proliferation.

Over time, the cell population increases exponentially, resulting in a larger quantity of cells compared to the initial sample.

3. Cell Differentiation

After cell multiplication, the cultured cells need to differentiate into the desired tissue types, such as muscle cells.

This process is achieved by manipulating the culture conditions, such as adjusting oxygen levels, nutrient availability, and introducing specific growth factors. Through careful control of these factors, the cells assume their desired characteristics and form muscle tissue that closely resembles conventionally produced chicken meat.

4. Scaffolding and Structuring

In order to create meat that resembles the texture and structure of conventional chicken, researchers use scaffolding techniques.

A scaffold, typically composed of edible materials like plant fibers or proteins, acts as a support structure for the growing cells. This allows them to align and attach to the scaffold, leading to the formation of muscle fibers that mimic the texture and appearance of natural chicken meat.

Benefits of Laboratory Chicken

The development of laboratory chicken offers numerous advantages:.

1. Animal Welfare

Laboratory chicken eliminates the need for traditional animal farming methods, reducing the suffering and mistreatment of animals.

It provides a cruelty-free alternative while still offering the same nutritional value and taste as conventionally produced chicken.

2. Environmental Impact

Conventional animal farming contributes significantly to greenhouse gas emissions, land degradation, and water pollution.

Laboratory chicken production requires fewer natural resources, produces lower greenhouse gas emissions, and minimizes environmental degradation compared to traditional farming methods. It presents a more sustainable option that can help mitigate the negative environmental effects associated with conventional livestock rearing.

3. Food Security

As the global population continues to grow, the challenge of feeding everyone becomes increasingly critical. Laboratory chicken could help address this issue by providing a more efficient and scalable method of meat production.

By utilizing bioreactors and controlled environments, laboratory chicken production can be optimized to produce a consistent and abundant supply of high-quality meat.

Controversies and Challenges

Despite its potential benefits, laboratory chicken faces some controversies and challenges:.

1. Acceptance and Perception

Consumer acceptance and perception play a significant role in the success of any new food product. Some individuals may be hesitant to embrace laboratory chicken due to skepticism or concerns about its safety and naturalness.

Raising awareness and promoting transparency about the production process will be crucial in addressing these concerns and fostering public acceptance.

2. Cost and Scalability

Currently, laboratory chicken production is expensive compared to conventional poultry farming. The cost of research, development, infrastructure, and regulatory compliance all contribute to higher prices.

However, as technology advances and economies of scale are achieved, the cost of laboratory chicken is expected to decrease, making it more accessible to consumers.

3. Regulatory Framework

Developing a regulatory framework for the production and labeling of laboratory chicken is essential. Ensuring that it meets safety and quality standards will be crucial in gaining the trust of consumers and avoiding potential controversies.

Regulatory bodies, such as the FDA, play a vital role in establishing guidelines and monitoring the safety of laboratory chicken products.

The Future of Laboratory Chicken

Laboratory chicken represents an exciting advancement in food technology and has the potential to revolutionize the meat industry. As research and development continue, there are several aspects that scientists and stakeholders are working on:.

1. Taste and Texture Refinement

Ensuring that laboratory chicken replicates the taste and texture of conventionally produced chicken is crucial for consumer acceptance.

Researchers are continually refining the production process to mimic the sensory attributes of natural meat more accurately.

2. Scaling Up Production

Currently, laboratory chicken production operates on a small scale. Scaling up this technology is necessary to make it commercially viable and meet the growing demand for alternative meat options.

Increasing production efficiency, optimizing bioreactor technologies, and reducing costs are areas where ongoing research and development efforts are focused.

3. Diversification into Other Meat Products

Laboratory chicken is just one example of the potential applications of cellular agriculture. Researchers are also exploring the production of other meat products, such as laboratory beef, pork, and fish.

Diversifying the range of alternative meat options will provide consumers with more choices and further contribute to a sustainable and cruelty-free food system.

Conclusion

The science behind FDA-approved “laboratory chicken” offers immense potential to address various challenges associated with traditional animal farming.

Through innovative technology and precise cell culture techniques, laboratory chicken combines animal welfare, environmental sustainability, and food security. While there are still hurdles to overcome, ongoing research and development in this field promise a future where laboratory chicken and other cultured meat products become more accessible and widely accepted.