Pressure is a fundamental force that we encounter in our daily lives. It plays a crucial role in numerous processes and applications across various industries. However, pressure can also pose significant risks if not properly managed.

It is important to identify the most unsafe pressure situations and take the necessary precautions to ensure the safety of individuals and equipment involved. This article will delve into the various aspects of unsafe pressure, its identification, and the importance of pressure management.

The Consequences of Uncontrolled Pressure

When pressure exceeds safe limits, it can lead to disastrous consequences. In industrial settings, over-pressurization can result in explosions, equipment failures, and injuries to personnel.

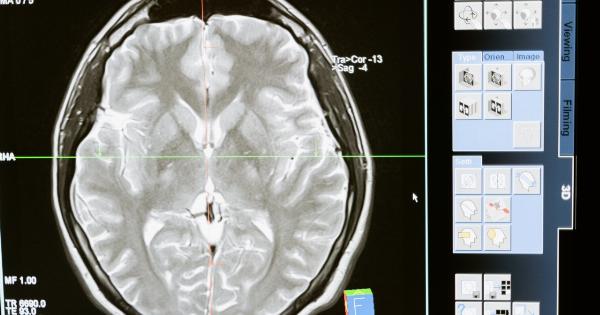

In the medical field, improperly managed pressures can cause damage to vital organs, leading to severe health complications. It is, therefore, crucial to identify and address situations where pressure exceeds safety thresholds.

Identifying Unsafe Pressure Scenarios

Unsafe pressure can occur in various environments and situations. Some common scenarios include:.

- High-pressure vessels and equipment

- Pipelines and hydraulic systems

- Chemical manufacturing processes

- Oil and gas drilling operations

- Pressure cookers and kitchen appliances

By recognizing and understanding these scenarios, individuals can be better equipped to identify potentially unsafe pressure conditions.

Factors Affecting Pressure Hazards

Several factors contribute to the hazards associated with pressure:.

- Pressure magnitude and duration

- The nature of the pressurized substance

- Temperature and environmental conditions

- Physical integrity of pressure-containing equipment

- Mechanical stresses and vibrations

Considering these factors can help in assessing the level of risk involved and taking appropriate measures to mitigate them.

The Importance of Pressure Management

Proper pressure management is essential for ensuring safety in various industries. It involves measures such as:.

- Regular inspection and maintenance of pressure systems

- Monitoring and controlling pressure levels

- Implementing safety devices and relief valves

- Employee training and awareness programs

- Following industry-specific guidelines and standards

By implementing these practices, the risks associated with high-pressure situations can be significantly reduced.

Risk Mitigation Strategies

To mitigate pressure-related risks, it is important to:.

- Evaluate and understand the pressure thresholds of equipment and systems

- Implement proper pressure relief mechanisms

- Conduct regular inspections and maintenance

- Perform thorough risk assessments and develop contingency plans

- Train personnel on safe handling and operation procedures

Adopting these strategies can help prevent accidents, injuries, and loss of life resulting from unsafe pressure conditions.

Applications of Pressure Management

Pressure management is crucial in a wide range of industries and applications:.

- Oil and gas extraction and refining

- Chemical and pharmaceutical manufacturing

- Power generation and distribution

- Food processing and packaging

- Medical diagnostics and treatment

Each of these industries has specific pressure requirements and safety guidelines that need to be followed to prevent hazardous situations.

Industry-Specific Pressure Standards

Various industry organizations and regulatory bodies have established specific pressure standards to ensure safety. Some examples include:.

- ASME Boiler and Pressure Vessel Code for the boiler and pressure vessel industry

- API standards for the oil and gas industry

- ISO 9001 standards for quality management systems, including pressure management

Adhering to these standards is crucial to maintaining safe pressure levels in the respective industries.

Conclusion

Recognizing and managing unsafe pressure is of utmost importance to prevent accidents, injuries, and even fatalities.

By understanding the factors affecting pressure hazards, implementing proper pressure management practices, and following industry-specific guidelines, the risks can be significantly reduced. Identifying unsafe pressure situations and taking appropriate measures is the key to ensuring the safety of individuals, protecting equipment, and preventing catastrophic incidents.